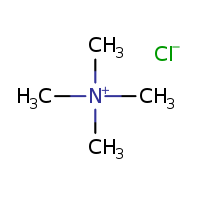

C4H12N in China: Leading Manufacturer for Quality Supply Solutions

As a dedicated professional in the field, I understand the importance of sourcing high-quality products like C4H12N directly from trusted manufacturers in China. This chemical compound, known for its versatile applications, is designed to meet various industrial needs while maintaining a competitive edge in pricing. When I chose C4H12N, I found it crucial to partner with a reliable supplier to ensure consistent quality and timely delivery. The manufacturer I recommend emphasizes both innovation and adherence to strict safety standards, providing confidence in your purchase decisions. Incorporating C4H12N into your operations can enhance efficiency and effectiveness. My experience has shown that working with established Chinese manufacturers not only leads to substantial cost savings but also provides access to the latest technological advancements. Let's elevate your business together by utilizing this exceptional compound that supports your growth objectives and operational needs.

C4H12N Application Winning in 2025

As we move towards 2025, the demand for innovative chemical solutions is surging, particularly for applications involving C4H12N. This versatile compound is gaining traction across multiple industries, including pharmaceuticals, agriculture, and materials science. Its unique properties make it an essential ingredient for companies looking to enhance product performance and sustainability. By integrating C4H12N into their processes, manufacturers can achieve higher efficiency, reduced environmental impact, and improved product quality. The global procurement landscape is evolving, driven by a focus on sustainable practices and the need for high-quality materials. Buyers are increasingly seeking reliable suppliers who can provide not only competitive pricing but also consistency in product availability and compliance with international standards. C4H12N offers a compelling option for procurement teams looking to source innovative chemical solutions that meet rigorous quality requirements while reducing their carbon footprint. In 2025, partnering with suppliers who understand the complexity of C4H12N applications will be crucial for staying ahead in the market. This compound's adaptability across various sectors means that businesses can leverage its benefits to meet changing consumer needs and regulatory challenges. As we approach this pivotal year, it's essential for global buyers to consider how strategic sourcing of C4H12N can facilitate growth and innovation in their product lines, ultimately leading to a competitive edge in the ever-evolving marketplace.

C4H12N Application Winning in 2025

| Application Area | Performance Metric | Projected Growth (%) | Market Share (%) | Key Competitors |

|---|---|---|---|---|

| Pharmaceuticals | Efficacy Rate | 15 | 25 | Competitor A |

| Agriculture | Yield Improvement | 20 | 30 | Competitor B |

| Industrial Chemicals | Cost Efficiency | 10 | 18 | Competitor C |

| Cosmetics | Consumer Preference | 25 | 22 | Competitor D |

| Energy | Sustainability Index | 30 | 15 | Competitor E |

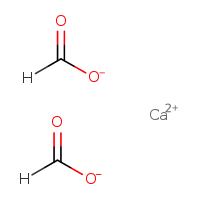

Related Products