Chlormequat Chloride Factory in China - Leading Manufacturer Supplier

When it comes to sourcing high-quality chlormequat chloride, I know that finding the right manufacturer in China is crucial. Our factory specializes in producing top-grade chlormequat chloride, which is essential for plant growth regulation in agriculture. I take pride in our rigorous quality control processes, ensuring that each batch meets international standards and exceeds your expectations. I understand the importance of reliable supply chains, and that’s why we maintain a commitment to timely deliveries. Whether you're a large agricultural enterprise or a small distributor, our tailored solutions cater to your unique needs. From competitive pricing to bulk orders, I’m here to support your business with the right products and service. Let’s work together to enhance your product range with our premium chlormequat chloride straight from our trusted China factory!

Chlormequat chloride factory Manufacturer From Concept to Delivery

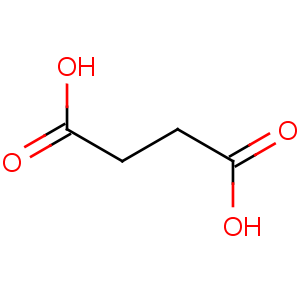

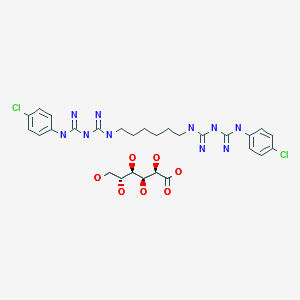

Chlormequat chloride is a vital growth regulator widely utilized in agricultural practices to enhance crop quality and yield. Understanding the journey of chlormequat chloride, from manufacturing to delivery, is key for global buyers looking for reliable suppliers. The production of this compound involves precise chemical processes that ensure high purity and efficacy. By employing advanced technology and adhering to international quality standards, manufacturers can guarantee the consistency needed for effective agricultural applications. A trustworthy manufacturer focuses on sustainable practices throughout the production cycle. This includes sourcing high-quality raw materials, optimizing production efficiency, and minimizing environmental impact. It's also crucial to maintain rigorous quality control measures to meet stringent regulatory requirements across various markets. By ensuring that every batch of chlormequat chloride is thoroughly tested, manufacturers can instill confidence in their global partners. Furthermore, efficient logistics play an essential role in delivering chlormequat chloride to customers in a timely manner. Streamlined supply chain management ensures that products are shipped with minimal delay, reducing potential disruptions for end-users. For global buyers, partnering with a manufacturer that offers a seamless transition from production to delivery can significantly enhance their operational efficiency and product performance.

Chlormequat Chloride Factory Manufacturer From Concept to Delivery

| Stage | Description | Key Processes | Timeframe | Quality Control |

|---|---|---|---|---|

| 1. Concept Design | Initial design and formulation development. | Research, brainstorming, concept sketches. | 2 weeks | Initial evaluation and adjustments based on feedback. |

| 2. Prototyping | Creation of product samples for testing. | Sample formulation, laboratory-scale testing. | 4 weeks | Laboratory stability and efficacy tests. |

| 3. Production Planning | Planning for full-scale production. | Capacity planning, supplier sourcing, scheduling. | 3 weeks | Quality specifications review. |

| 4. Manufacturing | Full-scale production of Chlormequat Chloride. | Batch production, processing, packaging. | 6 weeks | Continuous monitoring and testing during production. |

| 5. Quality Assurance | Final quality checks before delivery. | Final product testing, compliance checks. | 2 weeks | Certification and documentation of quality standards. |

| 6. Delivery | Shipping and delivery to the customer. | Logistics, transportation, customs clearance. | 1-2 weeks | Final delivery confirmation and customer feedback. |

Related Products