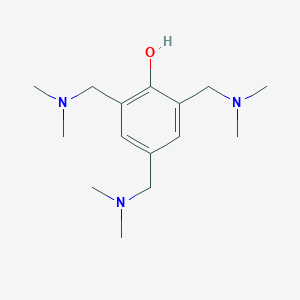

China Manufacturer of Tris(dimethylaminomethyl)phenol for Industrial Use

As a leading manufacturer in China, we take pride in offering high-quality Tris(dimethylaminomethyl)phenol, a versatile curing agent that enhances the performance of epoxy resins and adhesives. Our product is known for its excellent heat resistance and strong adhesive properties, making it an ideal choice for various industrial applications. When it comes to sourcing raw materials, I understand the importance of reliability and consistency. That's why I make sure that our Tris(dimethylaminomethyl)phenol meets international standards, ensuring it performs well under demanding conditions. We're committed to providing personalized service, competitive pricing, and timely delivery to support your manufacturing needs. By choosing our products, you’ll be partnering with a manufacturer who values your success as much as their own. Let's work together to elevate your production capabilities and achieve your business goals with our premium chemical solutions. Reach out today for samples and inquiries!

Tris(dimethylaminomethyl)phenol Industry Giant Service Backed by Expertise

In the rapidly evolving chemical industry, Tris(dimethylaminomethyl)phenol (also known as DMP-30) has established itself as a critical component in various applications, particularly in the fields of adhesives, coatings, and plastics. This versatile compound is praised for its effectiveness as a curing agent and its ability to enhance the performance and durability of end products. As global demand for innovative chemical solutions continues to rise, it is imperative for buyers to connect with industry leaders who understand the nuances of sourcing high-quality materials. Engaging with experts in the field allows procurement professionals to navigate the complexities of the market, ensuring they obtain not only competitive pricing but also products that meet rigorous safety and quality standards. An experienced partner in the chemical industry can provide invaluable insights into product formulations and best practices, helping businesses optimize their production processes. By leveraging deep industry knowledge, companies can gain a strategic advantage, ultimately leading to better product offerings and enhanced customer satisfaction. Moreover, sustainability has become a focal point in the chemical sector, pushing manufacturers to seek eco-friendly alternatives and practices. Collaborating with a supplier that prioritizes sustainable development can significantly impact a company’s reputation and compliance with environmental regulations. As global sourcing continues to expand, the importance of a trusted partner in the Tris(dimethylaminomethyl)phenol market cannot be overstated, as it not only facilitates efficient procurement but also fosters long-term business success.

Tris(dimethylaminomethyl)phenol Industry Giant Service Backed by Expertise

| Dimension | Description | Value |

|---|---|---|

| Chemical Formula | The chemical composition of Tris(dimethylaminomethyl)phenol | C15H21N3O |

| Molecular Weight | The weight of the molecule based on its chemical formula | 245.35 g/mol |

| Applications | Common uses of Tris(dimethylaminomethyl)phenol in the industry | Curing agent for epoxy resins, hardeners |

| Safety Information | General safety guidelines for handling | Wear protective gloves and eyewear |

| Storage Conditions | Ideal storage conditions to maintain stability | Store in a cool, dry place |

| Environmental Impact | Information regarding the ecological impact | May be harmful to aquatic life |

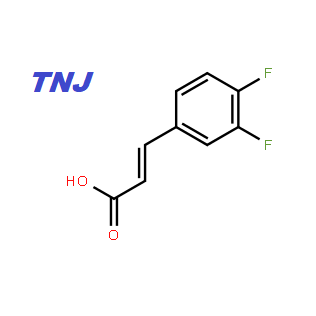

Related Products