Top 2-(4-Nitrophenyl)Ethanol Manufacturers in China

As a professional in the chemical manufacturing sector, I understand the importance of quality and reliability in sourcing 2-(4-nitrophenyl)ethanol. Our facility in China is dedicated to producing this compound with the highest standards in mind. With advanced technology and rigorous quality control, we ensure that our products meet the specific needs of B2B purchasers like you. We cater to various industries, and our commitment to excellence sets us apart from the competition. By choosing us as your manufacturer, you're not just getting a product; you're building a partnership that focuses on innovation and success. Get in touch, and let’s discuss how we can support your business needs with our superior 2-(4-nitrophenyl)ethanol. Together, we can drive your projects forward!

2-(4-nitrophenyl)ethanol manufacturers Ahead of the Curve Your End-to-End Solution

In the ever-evolving landscape of chemical manufacturing, sourcing high-quality intermediates can be challenging. One such compound, 2-(4-nitrophenyl)ethanol, stands out due to its versatile applications in pharmaceuticals and agrochemicals. As global procurement needs expand, manufacturers must stay ahead of market trends and regulatory standards to ensure a steady supply of this crucial chemical. The production of 2-(4-nitrophenyl)ethanol requires precise methodologies and stringent quality controls. Advanced synthesis techniques and reliability in sourcing raw materials are essential. By choosing a manufacturer that emphasizes both innovation and operational excellence, procurement professionals can secure a dependable supply chain. This end-to-end solution not only addresses the immediate needs of businesses but also fosters long-term partnerships built on trust and consistency. Embracing such comprehensive offerings enables companies to streamline their operations and reduce lead times. With a focus on quality and efficiency, manufacturers can help buyers navigate the complexities of global supply chains, ensuring that they receive the products they need, when they need them. The commitment to excellence in the production of 2-(4-nitrophenyl)ethanol represents a significant competitive advantage for companies looking to enhance their product lines and meet evolving market demands.

| Manufacturing Process | Quality Control | Applications | Safety Standards | Environmental Impact |

|---|---|---|---|---|

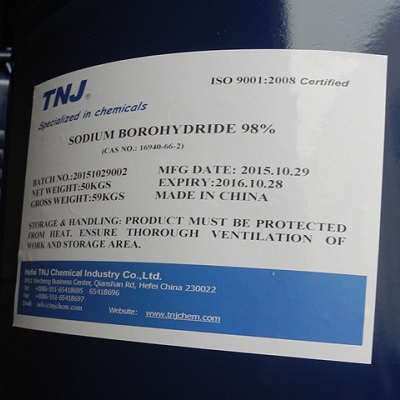

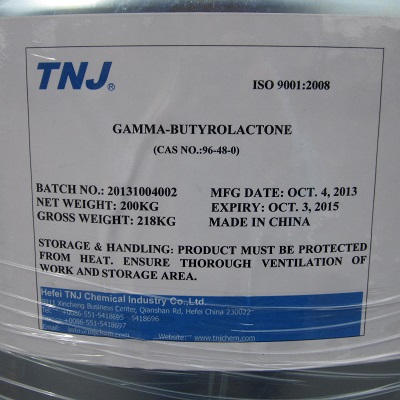

| Synthesis via alkylation | Routine analysis (HPLC, NMR) | Pharmaceutical intermediates | ISO 9001 compliant | Recyclable solvents used |

| Reduction of nitro compounds | Batch testing for purity | Chemical research | OSHA standards followed | Low emissions processes |

| Use of catalyst for efficiency | Stability testing | Industrial applications | REACH compliant | Minimal waste generation |

| Production scaling techniques | End-product evaluation | Agricultural chemicals | Good Manufacturing Practice (GMP) | Water-efficient processes |

Related Products