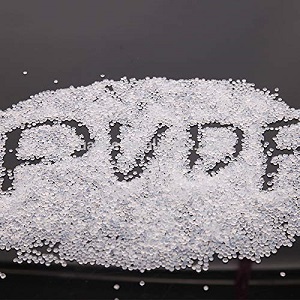

High Quality PVDF Resin from China Manufacturer - Best Selection Available

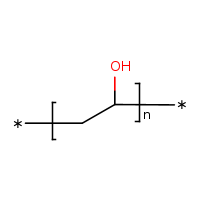

Are you in search of high-quality poly(vinylidene fluoride) PVDF resin? As a manufacturer based in China, we offer premium-grade PVDF resin that meets the diverse needs of various industries. I understand the importance of durability and performance in your applications, and our products are designed to deliver excellent resistance to chemicals, UV rays, and temperature fluctuations. Whether you’re working in the automotive, electronics, or chemical processing sectors, our PVDF resin can enhance your products' efficiency and lifespan. We take pride in our rigorous quality control processes to ensure you receive only the best materials. Let’s partner together to elevate your products with our reliable PVDF resin tailored for your specific requirements. Don't hesitate, get in touch today to learn how we can help you achieve your project goals!

Buy high quality poly(vinylidene fluoride) PVDF Resin Application Industry Giant

When it comes to sourcing high-quality poly(vinylidene fluoride) (PVDF) resin, a material renowned for its outstanding properties, the options in the market can be overwhelming. PVDF is widely recognized for its chemical resistance, exceptional durability, and high-temperature stability, making it the material of choice across various industries such as pharmaceuticals, chemicals, and electronics. This resin not only boasts excellent mechanical properties but also offers superior performance in hostile environments, where reliability is paramount. The growing demand for PVDF in energy applications, especially in solar panels and lithium-ion batteries, further highlights its significance in modern technological advancements. As global industries strive for sustainability and efficiency, PVDF’s role becomes increasingly vital. Moreover, the versatility of PVDF allows it to be easily processed into films, sheets, and coatings, expanding its applications even further. As such, procuring premium-grade PVDF resin can enhance product performance and provide a competitive edge in a rapidly evolving market. For global purchasers looking to invest in PVDF resin, the emphasis should be on quality, consistency, and supplier reliability. Engaging with trusted manufacturers who adhere to stringent quality control measures ensures that the resin meets industry standards and specific project requirements. By making informed sourcing decisions, companies can capitalize on the many benefits that high-quality PVDF resin has to offer, ultimately driving innovation and growth within their sectors.

Buy high quality poly(vinylidene fluoride) PVDF Resin Application Industry Giant

| Application Industry | Market Demand (MT) | Growth Rate (%) | Key Properties | Secondary Uses |

|---|---|---|---|---|

| Electronics | 1000 | 10 | High chemical resistance, low thermal conductivity | Insulators, cables |

| Aerospace | 800 | 8 | Low flammability, excellent durability | Seals, coatings |

| Automotive | 1200 | 7 | High impact resistance, low density | Interior components, fuel lines |

| Medical | 600 | 12 | Biocompatibility, thermal stability | Pipes, blood bags |

| Construction | 700 | 5 | UV resistance, anti-corrosion | Roof membranes, wall cladding |

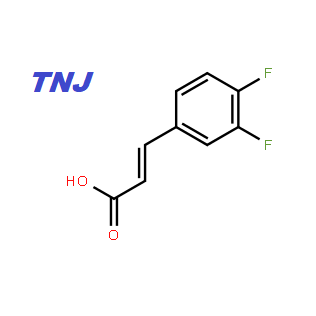

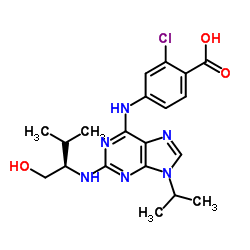

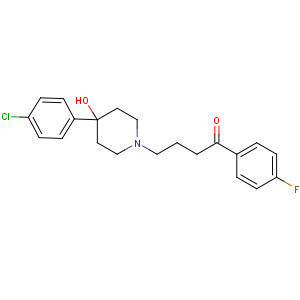

Related Products