Tetrabromophthalic Anhydride Manufacturer in China - Quality Solutions

As a professional in the chemical industry, I understand the growing demand for high-quality materials like Tetrabromophthalic anhydride. Sourced from leading manufacturers in China, this compound is essential for producing flame retardant polymers and resins. With its exceptional thermal stability and effective flame resistance, it is ideal for a variety of applications, whether it’s in electronics, textiles, or construction. In my experience, partnering with a reliable manufacturer can significantly impact production efficiency and product quality. That's why I emphasize the importance of choosing trusted suppliers who adhere to strict quality standards. By selecting Tetrabromophthalic anhydride from reputable sources in China, you can ensure that your finished products meet the necessary performance requirements. Let’s work together to elevate your product offerings with this versatile anhydride. I am committed to providing the best solutions tailored to your specific business needs. Feel free to reach out for more information or a quote!

Tetrabromophthalic anhydride Delivers Unmatched Quality Supplies the World\u2019s Top Brands

Tetrabromophthalic anhydride (TBPA) has emerged as a game-changer in the chemical industry, offering unparalleled quality that meets the exacting standards of the world’s leading brands. As a key fire retardant and plasticizer, TBPA is essential in various applications, including electronics, automotive, and construction. The consistent high quality of TBPA ensures that manufacturers can produce safer, more durable products, while also complying with stringent regulatory requirements. What sets TBPA apart is its exceptional performance in enhancing product safety and longevity. With its superior thermal stability and low volatility, TBPA not only improves fire resistance but also contributes to the overall structural integrity of materials. This makes it an indispensable component for companies striving to uphold their reputations for quality and reliability. As global demand for high-performance materials continues to rise, the supply of top-notch TBPA becomes a crucial consideration for procurement managers across various sectors. For businesses focused on innovation and sustainability, integrating TBPA into their supply chains can bring a competitive edge. By aligning with suppliers that prioritize quality and consistency, companies can ensure that they meet the evolving demands of the market while fostering trust with their customers. As we navigate a rapidly changing industrial landscape, the commitment to providing unmatched quality through Tetrabromophthalic anhydride will undoubtedly shape the future of manufacturing excellence.

Tetrabromophthalic Anhydride Delivers Unmatched Quality Supplies the World’s Top Brands

| Property | Value |

|---|---|

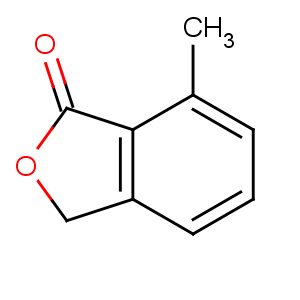

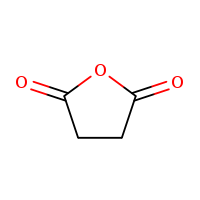

| Molecular Formula | C14H6Br4O3 |

| Molecular Weight | 485.81 g/mol |

| Appearance | White to light yellow crystalline powder |

| Melting Point | 216-220 °C |

| Solubility | Soluble in organic solvents, insoluble in water |

| Applications | Used in the production of flame retardants, and as a reactive intermediate in polymer synthesis |

| Safety Information | Handle with care; may cause skin and eye irritation |

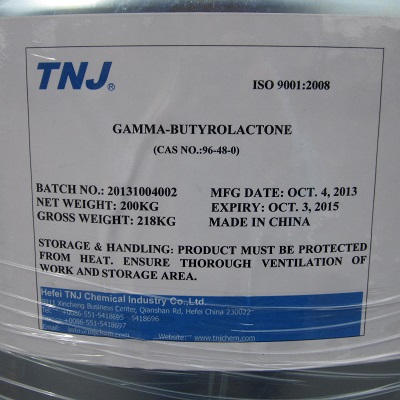

Related Products