Best Price of Phenyl Methacrylate | Leading Manufacturer in China

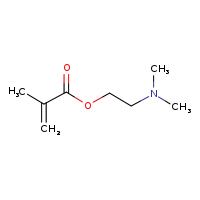

As a seasoned buyer in the industry, finding the **best price of Phenyl Methacrylate** is essential for my operations. Sourcing directly from a reliable **China manufacturer** not only ensures quality but also enhances my supply chain efficiency. The versatility of Phenyl Methacrylate makes it an attractive choice for various applications, from adhesives to coatings. I've seen firsthand how working with a trusted supplier can lead to significant cost savings and consistent supply. When I evaluate potential partners, I focus on product quality, pricing, and their ability to meet demands promptly. By choosing a manufacturer based in **China**, I benefit from competitive pricing without compromising on material integrity. Whether I'm looking to expand my product offerings or streamline costs, securing the best price for Phenyl Methacrylate is always a priority. Partnering with a reliable manufacturer can make all the difference in achieving my business goals and maintaining customer satisfaction.

Best price of Phenyl Methacrylate Industry Giant From Concept to Delivery

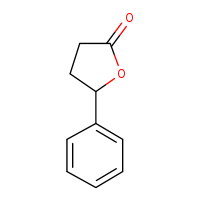

In the dynamic world of chemical manufacturing, Phenyl Methacrylate (PMA) stands out as a vital component across various industries, from coatings to adhesives. Companies depend on a reliable source that not only offers high-quality PMA but also ensures competitive pricing and timely delivery. For global buyers, securing a dependable supplier who understands market demands and adheres to strict quality standards is crucial. The production of Phenyl Methacrylate involves intricate processes that require expertise and state-of-the-art technology. By collaborating with industry leaders, buyers can benefit from optimized supply chains that reduce costs while maintaining product integrity. Moreover, effective communication with suppliers during the entire procurement process—from initial concepts to final delivery—ensures that buyers’ unique needs are met, fostering long-term partnerships that boost operational efficiency. Choosing the right supplier can make a significant difference in overall project success. As the Phenyl Methacrylate market evolves, those who leverage innovation and strategic planning will pave the way for growth. Buyers are encouraged to seek out partners who not only provide competitive rates but also prioritize sustainability and cutting-edge production techniques, ensuring their businesses thrive in an increasingly competitive landscape.

Best Price of Phenyl Methacrylate Industry Giant From Concept to Delivery

| Category | Dimension | Application | Advantages |

|---|---|---|---|

| Standard Grade | 1.0 - 1.2 g/cm³ | Adhesives | High adhesion |

| High Purity | 1.2 - 1.3 g/cm³ | Coatings | Enhanced durability |

| Specialty Grade | 1.3 - 1.4 g/cm³ | Plastics | Custom formulations |

| Agricultural Grade | 1.0 - 1.2 g/cm³ | Fertilizers | Eco-friendly |

Related Products