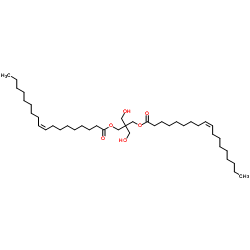

Pentaerythritoldioleate from Leading Manufacturer in China

Are you searching for high-quality Pentaerythritoldioleate? As a seasoned manufacturer based in China, we understand the importance of reliable ingredients for your products. Our Pentaerythritoldioleate is crafted to meet stringent standards, ensuring excellent performance in various applications. This versatile compound is known for its outstanding stability and low viscosity, making it ideal for uses in lubricants, coatings, and plasticizers. What sets us apart is our commitment to quality and customer satisfaction. I personally ensure that every batch meets our rigorous quality control measures so you can trust what you’re getting. With years of experience in the industry, we’re proud to support businesses like yours with tailored solutions to fit your specific needs. Let’s partner up to enhance your product offerings and drive your success! Reach out today to discuss how our Pentaerythritoldioleate can make a difference for you.

Pentaerythritoldioleate Factory Outperforms the Competition

In the highly competitive landscape of chemical manufacturing, the production of pentaerythritoldioleate has emerged as a critical focus for industry players aiming to deliver superior quality and value. A leading factory specializing in this compound has successfully set itself apart through innovative processes, stringent quality control, and a strong commitment to sustainability. By implementing state-of-the-art technology and adhering to international standards, the factory ensures that its products not only meet but often exceed customer expectations. Global procurement professionals are increasingly prioritizing suppliers that demonstrate reliability and excellence. This top-tier factory has cultivated a reputation for delivering consistent, high-quality pentaerythritoldioleate, ideal for various applications including lubricants, plasticizers, and coatings. Its strategic sourcing of raw materials and optimized production techniques reduce costs, ultimately passing savings to clients while maintaining product integrity. As a result, buyers can leverage these advantages to enhance their own offerings in a market that demands both quality and performance. Furthermore, sustainability is at the core of the factory's operations. By implementing eco-friendly practices and reducing waste throughout its production cycle, the facility aligns with the growing demand for environmentally conscious products. This not only helps procurement teams meet their corporate social responsibility goals but also attracts consumers who are increasingly discerning about the products they choose. In a time of rapid change and increasing competition, partnering with a manufacturer that prides itself on innovation, quality, and sustainability can provide a significant edge in the global market.

Pentaerythritoldioleate Factory Outperforms the Competition

| Parameter | Factory A | Factory B | Factory C |

|---|---|---|---|

| Production Capacity (tons/month) | 1500 | 1200 | 1000 |

| Quality Certification | ISO 9001 | ISO 9001 | None |

| Average Lead Time (days) | 15 | 20 | 30 |

| Customer Satisfaction (%) | 95 | 90 | 85 |

| Energy Efficiency (%) | 90 | 85 | 80 |

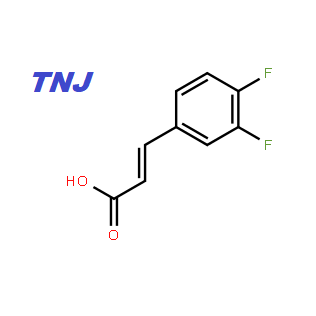

Related Products